Electrical Thermography –

Level 2 Infrared Inspection

by Snell-Certified Technicians

Electrical Thermography – Level 2 Infrared Inspection

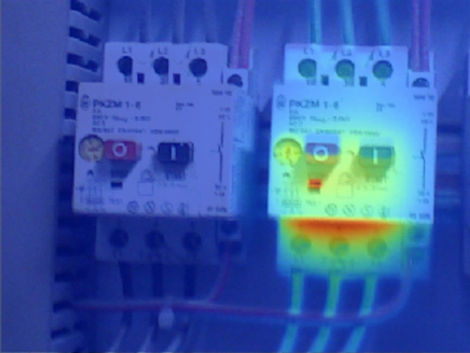

Electrical thermography makes it possible to detect abnormal heat zones in energized equipment — without contact.

It is an essential method to prevent failures, reduce production downtime, and improve the safety of your installations.

Why Choose a Level 2 Thermography Inspection?

The difference between a standard thermography inspection and a Level 2 inspection lies in the depth of analysis.

Our technicians, certified by The Snell Group (a globally recognized organization), go beyond simply capturing thermal images.

They accurately interpret the results, distinguish true anomalies from reflections or material effects, assess the severity of each issue, and provide corrective recommendations.

All reports comply with international standards and can be directly used by your maintenance teams.

Our Strengths

-

Level 2 Certified Technicians – Snell Group

-

Over 20 years of experience in industrial inspections across Québec and Canada

-

Services tailored to various sectors: sawmills, paper mills, aluminum plants, and manufacturing facilities

-

Accurate, standardized reports delivered promptly

-

Service coverage: Québec and Chaudière-Appalaches regions

Common Applications

-

Electrical Control Panels (MCCs, Motor Control Centers)

-

Transformers and Circuit Breakers

-

Industrial Motors and Wiring

-

Power Lines, Connections, and Busbars

Added Value for Your Operations

An advanced thermographic inspection allows you to:

-

Quickly identify critical areas before they lead to a failure

-

Reduce unplanned downtime and associated costs

-

Improve electrical safety within your facilities

-

Plan effective preventive maintenance

-

Extend the lifespan of your key equipment

FAQ – Level 2 Electrical Thermography

-

What is the difference between a standard thermography inspection and a Level 2 inspection?

A standard thermography inspection is limited to capturing infrared images.

A Level 2 inspection includes advanced interpretation — confirming anomalies, assessing their severity, and providing corrective recommendations.

-

Do I need to stop production for the inspection?

No. The inspection is performed under load, without contact, allowing your operations to continue without interruption.

-

Which equipment can be inspected?

We inspect cables, circuit breakers, transformers, motors, control panels, and MCCs.

-

What are the benefits for my plant?

Fewer unexpected shutdowns, increased safety, better maintenance planning, and longer equipment lifespan.

-

Why choose EBI Electric?

Because we combine international certification, on-site experience, and standardized reports that your teams can use immediately.

Contact us

Do you want to secure your installations and avoid unexpected downtime?

1 888 228-5505