Understanding Dynamic Balancing and Its Importance

- Sep 8, 2023

- 1 min read

Updated: Jun 26, 2024

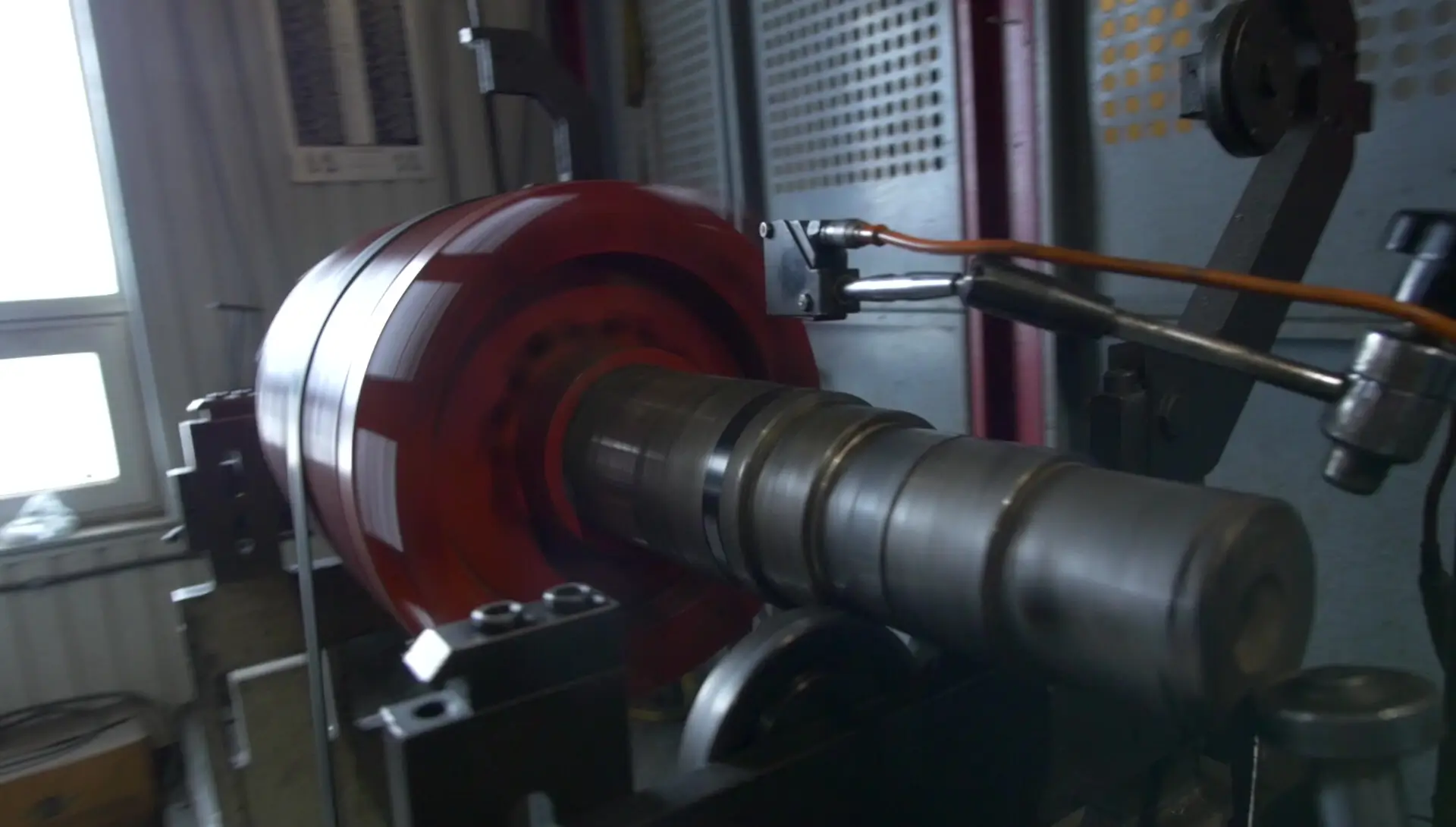

Dynamic balancing is the process of aligning the moving parts of a machine or other rotating parts to prevent breakdowns and ensure smooth operation. It involves measuring the imbalance of the machine using sensitive electronic equipment while it rotates rapidly. Dynamic balancing is essential for ensuring the longevity of industrial machines and other rotating equipment as well as for preventing costly breakdowns and repairs. By correcting any imbalances detected during the dynamic balancing process, machines can operate more efficiently with reduced noise and vibration.

The importance of dynamic balancing in industrial machines cannot be overstated. Unbalanced machines can cause a range of negative effects, including increased noise and vibration, reduced efficiency, and decreased lifespan of the machine. High levels of vibration caused by unbalance can also lead to decreased reliability and increased energy usage. Dynamic balancing minimizes these risks by ensuring that machines operate smoothly and efficiently with minimal noise and vibration. Additionally, dynamic field balancing allows for equipment to be balanced in place at specified running speeds, reducing the need for disassembly and transportation to a balancing facility.

In summary, dynamic balancing is a crucial process for ensuring the smooth and efficient operation of industrial machines and other rotating equipment. By minimizing vibration and noise, reducing energy costs, and extending the lifespan of machines, dynamic balancing can provide a range of benefits for businesses and industries. Whether through static or dynamic balancing, correcting imbalances in rotating equipment is essential for minimizing the risk of breakdowns and ensuring reliable and efficient operation.