Electrical Installation of a Lumber Dry Kiln

- Oct 15, 2023

- 1 min read

Updated: Jun 26, 2024

Electrical Wiring of a Lumber Batch Kiln

The method of wiring and connecting the electrical equipment of a lumber dry kiln such as the control panels must be adapted to the environment of the dry kiln. For each electrical connection that is not waterproof, there is a risk of condensation and even infiltration of water and steam into a control panel; otherwise, premature wear and component oxidation will occur. In some cases, short circuits can be triggered. It is not recommended to use non-waterproof pipes, steel or tinplate locknuts or BX connectors. Below is an example of premature wear of a transformer due to oxidation.

Below, we notice a breakdown of components due to corrosion.

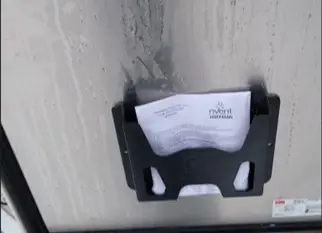

Condensation inside the control panel is noted below. The BX gauge protection and the BX connector are not water and steam proof.

It is also important to mention the importance of avoiding the use of SEW-type wires. These are not approved for lumber kiln wiring.

To ensure optimal electrical installation of a lumber dry kiln, entrust such installation to a certified industrial electrician contractor that has considerable experience and knowledge of the wood manufacturing industry. At EBI Electric, not only do we have experience in the field of lumber dry kiln electrical installation, we also manufacture high temperature electric motors for the lumber drying industry.